IN SITU TEST

AND DIAGNOSTICS

OUR TEST SECTORS:

STATIC AND DYNAMIC LOAD TESTS

P&P performs static and dynamic load tests on multiple types of structures in the civil and industrial fields, as well as in the infrastructure sector.

The tests can be carried out during the construction phase on parts of the work to verify the hypotheses underlying the project and to evaluate the correct execution of the structure in progress.

Experimentation is then used in the testing phase to determine the actual behavior of the structure by identifying and verifying the schemes and project assumptions adopted. It is thus possible to guarantee, beyond any uncertainty of design or construction, the compliance of the work with the required reliability and safety requirements. Finally, load tests are also frequently conducted during operation, both for reclassification needs and for checking the state of the work during its useful life, in order to capture and quantify any deterioration or damage that has occurred. over time in the static structure of the structure.

The dynamic tests allow to characterize the overall behavior of the work and are of fundamental utility for checks in seismic areas. P&P has special equipment (mechanical vibrodyne, hydraulic vibrodyne, electrodynamic exciters, ...) for the application of loads, for measuring the response of the structure and for processing experimental data.

RELIEF OF VIBRATION AND NOISE

P&P carries out surveys of vibrational and acoustic disturbances induced on buildings or sensitive elements.

Surveys are also carried out aimed at characterizing the vibrations present on plants and machinery for intensity checks and for the study of insulation interventions.

CONTROLLED LIFTINGS

P&P manufactures controlled lifting systems with automatic monitoring for fixed applications or for impromptu construction site activities.

Loads can be applied at different points at the same time, monitoring displacements and stresses through centralized control systems with wide adjustment possibilities.

SURVEY - INVESTIGATIONS - MONITORING

DIGITAL SURVEYS AND BIM

The potential to obtain an extremely accurate survey of the geometry and state of conservation of the works and artefacts allows the application of this ...

ACOUSTICS AND VIBRATIONS

In the field of environmental acoustics, P&P boast an important experience both in the execution of acoustic monitoring campaigns and in the execution of studies ...

STRUCTURAL MONITORING

P&P designs, manufactures and installs static and dynamic monitoring and surveillance systems equipped with specific automatic management software.

BRIDGES AND INFRASTRUCTURE

Road and rail transport infrastructures have always been part of the P&P Group's scope of intervention which supports the managing body of the road infrastructure in ...

MONITORING SYSTEMS

P&P designs, manufactures and installs static and dynamic monitoring and surveillance systems equipped with specific automatic management software.

It also offers the possibility of data transmission via GSM / Wireless with remote control, alarm threshold management and interpretative analysis of the data provided by the monitoring system.

These systems allow you to continuously measure vibration levels and monitor the evolution of crack patterns and settlements using strain gauges, inclinometers and level meters.

Seismic monitoring systems are also created with remote control and contextual survey of the parameters related to the stability of the structure.

P&P also manages the monitoring of landslides and slope instability.

NON-DESTRUCTIVE CHECKS AND DIAGNOSTICS

There is a wide range of tools and techniques of relief to evaluate the actual integrity of a work and to check the state of conservation of the materials. P&P uses multiple testing methods applicable to structures already in operation or under construction.

The diagnostic intervention program provides for the definition of the types and number of control techniques, considering the following main aspects:

-

- type of work: concrete, masonry, steel

- information on geometries, dimensions, nature of materials, integrity of components, etc ...

- accessibility on the work

- speed of execution of the intervention and estimate of the extent of any period of outage of the work

The experience and specific expertise in the fields of civil and industrial construction, transport infrastructures, monumental assets and industrial plants, allows P&P to offer its customers the optimal solution.

Sclerometric tests

Sonic tests

Pull out tests

Pull off tests

Single and double flat jacks

Shear tests on masonry

Coring on concrete

Video inspections and endoscopies

Surveys of reinforcement bars with probes and with covermeter

Relief of the shot in the chains

Deformation and tension measurements

Load tests on plate and soil bearing capacity

Load tests on piles and foundation works

Geometric, structural and topographical surveys

Ultrasound Surveys of thicknesses of metal materials

Control of welds by magnetic particles

Control of welds by ultrasound

Bolt tightening with torque wrench

Shear tests on masonry and wall panels

Moisture measurement on wood and masonry

Penetrometric tests on wood

Tests with Resistograph on wood

Woodpecker Tests

Masonry extraction tests

Infrared camera

Cross hole tests on poles and diaphragms

Non-destructive tests on piles and pit foundation works / electrodynamic exciter

Extraction tests on anchoring systems and tie rods

Tightness tests for sewer pipes

Absorption tests on masonry and wall panels

Tests on industrial floors

Tests on mortars, plasters and stone materials

Survey of the state of stress on reinforced concrete elements

Friction tests Skid Test

THERMOGRAPHY

Thermography is an effective diagnostic technology in various fields of application, including construction and the industrial sector. Through the use of infrared cameras, it is possible to make visible and analyze the emission of energy in the form of infrared rays, which all bodies emit, otherwise invisible to the human eye. By carrying out non-destructive and non-invasive checks, the two-dimensional graphic display of the irradiation measurement is obtained.

Thermography allows you to view absolute values and temperature variations of the artifacts regardless of their illumination in the visible range. It thus allows us to identify anomalies in the energy emission of a body.

All thermographic measurements are carried out by 2nd level personnel according to ISO 9712 UN EN 473 standards.

Main fields of application of infrared thermography services:

1. Industrial equipment and production sites

In situ analysis (analysis of industrial chimneys and thermal insulation, thermographic verification of the refractory insulation of cement factories, ovens, foundry hoppers, etc ...)

Investigations on pipelines (verification of insulation of industrial heating distribution systems and large manifolds, etc ...)

Specialized sectoral thermal analyzes (thermographic evaluation of the insulators of railway carriages, control of industrial discharges, landfill land verification, etc ...)

2. Civil and industrial electrical systems

Checks on civil and industrial electrical systems (measurement of the insulation resistance of the electrical cables and the floor, measurement of the resistivity of the ground, functionality of the RCDs, etc ...)

Checks and tests on photovoltaic systems

Measurement services compliant with the requirements of the CEI 82-25 standard

Thermographic analysis of electrical systems (thermal analysis of LV electrical panels and their live components, analysis of medium voltage panels equipped with IR windows, etc...)

3. Residential and industrial buildings

Thermographic appraisals with legal validity in the event of a dispute (verification of thermal coats and thermal bridges, etc.)

Thermographic checks on buildings (complete thermal mapping even of large surfaces, thermography for certifications, consultancy for thermal insulation, heat loss, assessment and control of windows, support for energy certifications, etc.)

Thermal bridges and molds (thermographic verification of thermal bridges, thermo-hygrometric verification of environmental parameters, verification of infiltrations, investigations to search for leaks in heating systems, etc ...)

ANALYSIS OF THE WOODEN STRUCTURES

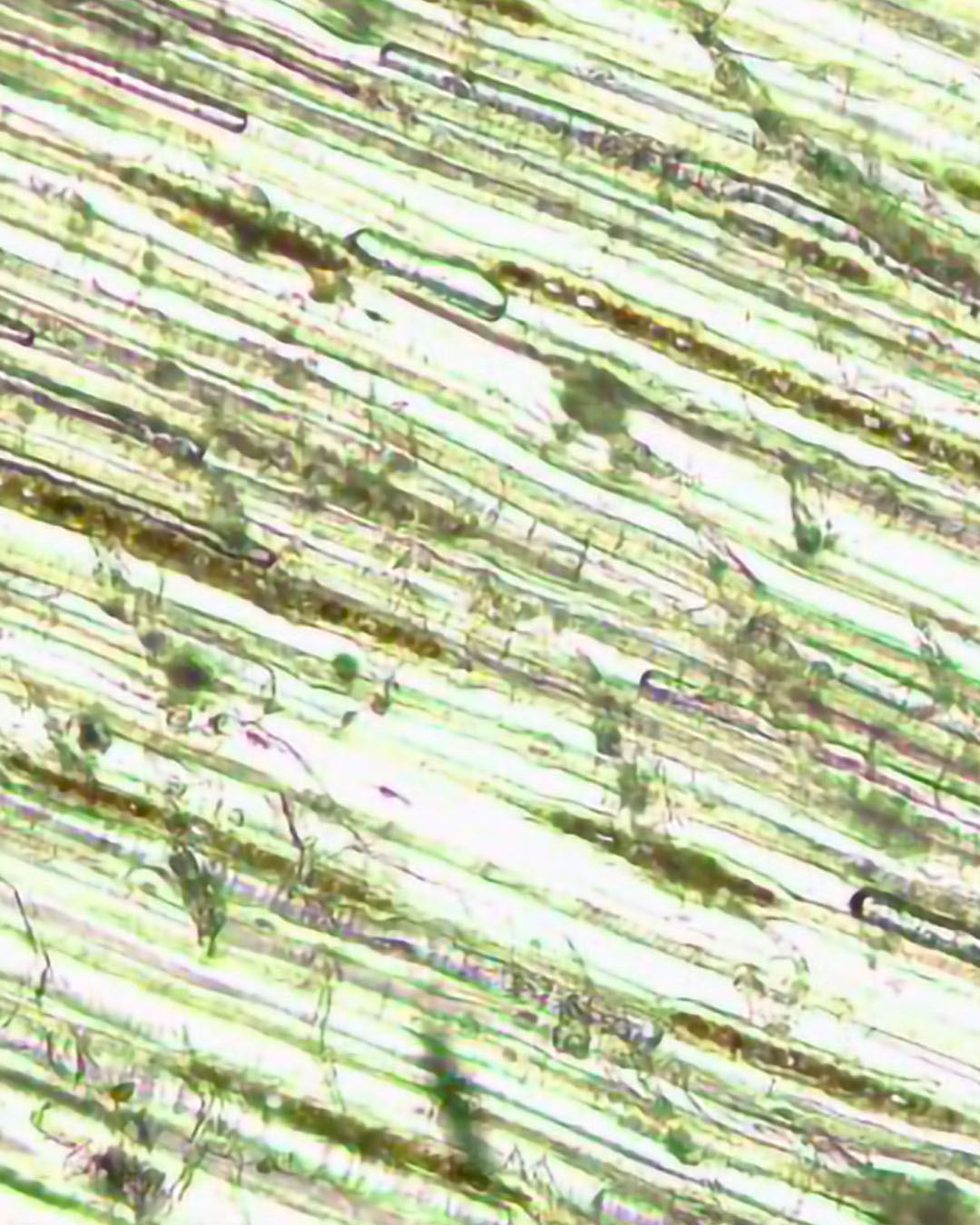

P&P performs analyzes on wooden structures to provide indications for the purpose of a qualitative assessment of the wood samples examined and then proceed to the recognition of the wood species through the anatomical characterization of the cellular elements, as reported in the UNI 11119 standard of 2004.

The main investigations conducted are:

- Visual inspection of the wooden structure and mapping of degradation: macroscopic analysis of the wood species based on the recognition of the presence of the anatomical elements detectable on the basis of visual examination.

- Penetrometric tests with Resistograph: instrumental analysis that allows to integrate the analyzes carried out visually. The Resistograph is, in essence, an instrumented drill capable of recording the resistance that the wood opposes to the entry of a tip equipped with a combined movement of rotation and advancement at a constant speed. Furthermore, the test allows to analyze inaccessible portions of the structure, that is the internal parts and the supports on the walls.

- “Wood Pecker” wood hammer: the Woodpecker is basically a penetrometer that uses a hammer equipped with a needle that is inserted into the wooden fabric. It is possible to correlate the sinking of the needle and the relative number of strokes necessary for the insertion to the mechanical characteristics, the nature of the wooden material and its conservation within the investigated element. The test method is therefore particularly suitable for the mechanical evaluation of the wooden tissue on site.

- Hygrometric tests on wood: a digital wood hygrometer is used to evaluate the relative humidity in wooden elements. This instrument is a digitally mounted humidity meter capable of determining the amount of water inside the different elements with automatic compensation based on the environmental temperature.

- Sonic investigations on wooden elements: the test allows to collect elements of evaluation regarding the homogeneity of the characteristics of the wood among the various elements examined.

- Laboratory tests on wooden beams and joists: execution in the laboratory of bending breaking load tests. The test lay-out is achieved by placing the samples on articulated supports and applying a concentrated load in the middle of the element with the aid of a hydraulic jack. To measure the vertical displacements, an electrical centesimal displacement transducer is used, located in the middle of each beam under test.

- Collection and laboratory analysis of wooden samples: the samples are subjected to macro and microscopic observation. The recognition of the wood species is achieved through the anatomical characterization of the cellular elements, as reported in the UNI 11118 standard of 2004. In the laboratory the samples are moistened with water and cut according to the canonical directions for the microscopic analysis of the wood (transverse, longitudinal radial and longitudinal tangential).

TESTS ON POLES

P&P performs numerous types of tests for the characterization of foundation structures with reference to piles and diaphragms. Specifically, the following are performed:

- Static load tests on poles even with high thrust loads: : static load tests with measurement of the displacements of the pole or micropile aimed at testing the product, conducted with thrust systems even at high load.

- Extraction tests on micropiles: extraction tests on micropiles for the testing of manufactured items sized for tensile loads

- Non-destructive tests with ecometric method (mechanical admittance with top impulse): verification of the length of the pole or micropile and integrity of the section along the shaft by analyzing the response to a sonic impulse impressed at the head of the product

- Dynamic tests with low or high energy vertical axis excitation (mechanical admittance with vertical exciter): verification of the length of the pole or micropile and integrity of the section along the shaft by analyzing the response to a vibratory stress impressed on the head of the product through an electrodynamic exciter with vertical axis operating in the frequency range 50 ÷ 1000 Hz. In addition to what can be deduced from the ecometric tests, it is possible to evaluate the behavior of the pole through some indications relating to the pole-ground interaction.

- Dynamic tests with high-energy vibrodine with counter-rotating shafts: verification of the length of the pole or micropile and integrity of the section along the shaft by analyzing the response to a vibratory stress impressed on the head of the product through an electrodynamic exciter with counter-rotating shafts operating in the frequency range 1 ÷ 50 Hz. In addition to what can be inferred from the ecometric tests, with reference to the pole-ground interaction, it is possible to evaluate the degree of constraint of the building and an estimate of the bearing capacity through the use appropriate correlation formulas.

- Sonic cross-hole investigation: verification of the length of the pole or micropile and integrity of the section along the shaft through the analysis of the response to a sonic excitation impressed by means of probes lowered into specially prepared tubes before casting the pole. The test also shows in graphic form the behavior and geometric characteristics along the development of the pole examined.

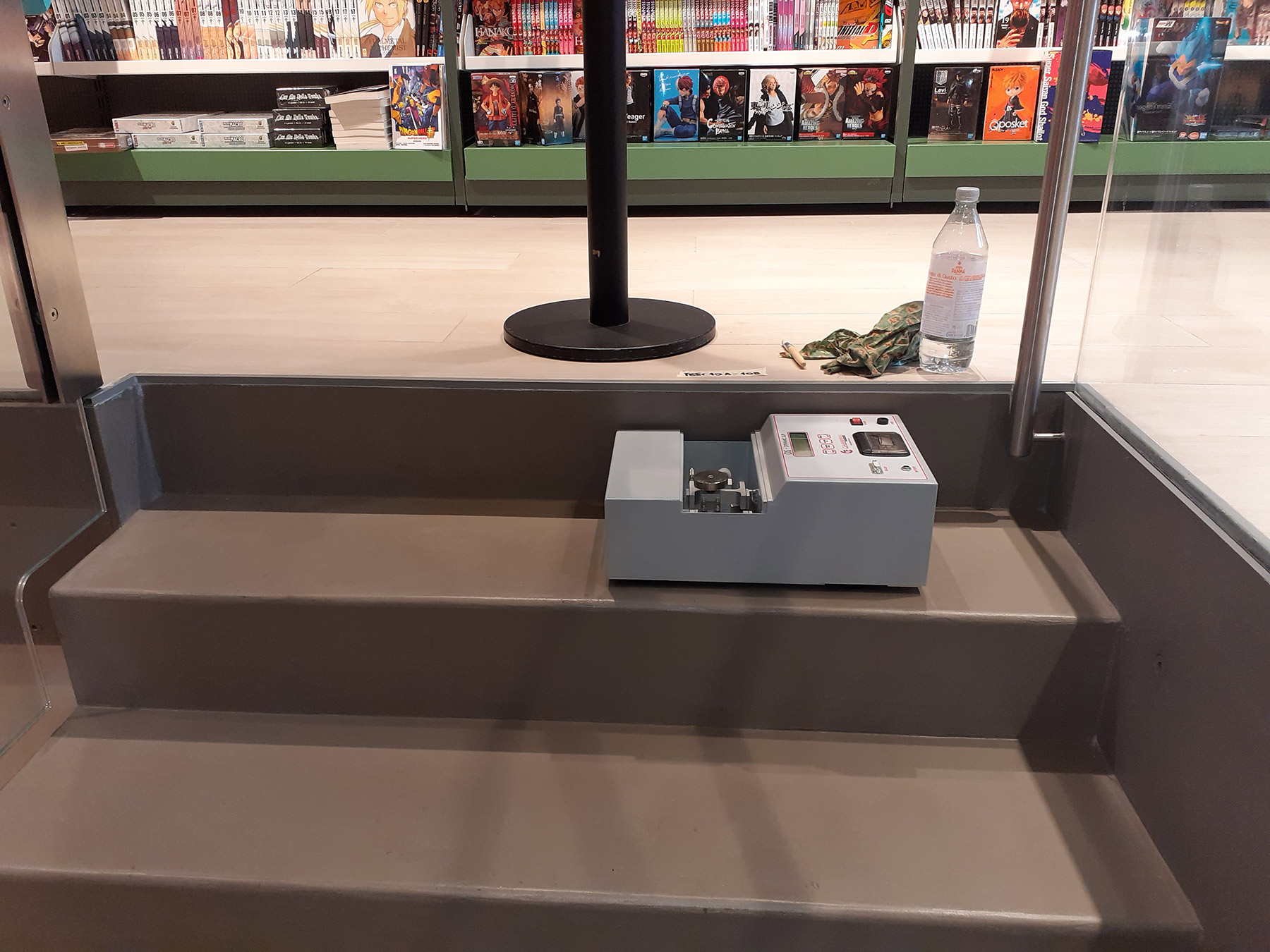

SLIPPITY TEST CARRIED OUT USING A DIGITAL SLIPPERIMETER

The slipperiness test performed on flooring is carried out to detect the dynamic friction coefficient, determined in the actual conditions of use of the flooring, as required by Italian law DM 236/89 art. 8.2.2.

The Italian Ministerial Decree n. 236 of 1989 ("Technical requirements necessary to guarantee the accessibility, adaptability and visitability of private buildings and subsidized and subsidized public residential buildings, for the purpose of overcoming and eliminating architectural barriers", Published in the Official Gazette no. 145 of 23 June 1989), in point 8.2.2 "Floors", establishes that floorings must be non-slip, meaning floorings made with materials whose friction coefficient, measured with the B.C.R.A. method, is higher to the following values:

- 0.40 for leather sliding element on dry pavement

- 0.40 for standard hard rubber sliding element on wet pavement

P&P offers slipperiness tests using the Dynamic Slip DS slipperimeter, which allows the dynamic friction coefficient COF to be determined with the B.C.R.A. method, therefore in line with the Ministerial Decree. n. 236/1989.

P&P also carries out tests using the pendulum equipment called Skid Tester which provides the SRV Slip Index to be related to the comparison values recommended by the UK Slip Resistance Group.

|

Attitude to the slipperiness of the surface |

SRV |

|

High |

less than 19 |

|

Moderate |

20÷39 |

|

Low |

40÷74 |

|

Extremely Low |

over 75 |

Reference standards:

ASTM E303: Measuring surface frictional properties using the British Pendulum Tester

The Assessment of Floor Slip Resistance – Guidelines – UK Slip Resistence Group – January 2006

IN SITU ROCKWELL HARDNESS TESTS

To characterize the type of steel used for metal carpentry structures, non-destructive Rockwell hardness tests are carried out according to UNI EN ISO 6508.

The measurement of the in-situ surface hardness of the steel (resistance that the surface of the material opposes to its penetration) allows us to deduce the mechanical tensile strength class of the material. To carry out the tests, a durometer capable of directly providing the resistance of the material was used.

These investigations were carried out referring to the Rockwell hardness scale, but with the same methodology it is possible to carry out tests with other scales, such as Brinell according to the UNI EN ISO 6506 standard, Vickers according to the UNI EN ISO 6507 standard, Lebb according to the UNI EN ISO 16859 standard.

DIAGNOSTICA SU TORRI FARO

P&P esegue attività complete di diagnostica strutturale su torri faro, finalizzate a valutarne lo stato di conservazione, la sicurezza e l’idoneità all’uso nel tempo. Le indagini vengono svolte con tecnologie avanzate e metodologie non distruttive, nel pieno rispetto della struttura esistente.

Attività svolte:

-

Rilievi geometrici di verticalità: acquisizione della geometria complessiva della torre tramite ispezione aerea con drone e tecnologia Laser Scanner 3D;

-

Analisi dei materiali: determinazione delle caratteristiche geometriche e meccaniche del fusto attraverso indagini non distruttive (spessimetro, durometro, ecc.);

-

Controllo delle saldature: ricerca di eventuali difetti nelle principali saldature (longitudinali e di base);

-

Esame visivo ravvicinato: ispezione dettagliata lungo l’intera altezza della torre per valutare lo stato di conservazione di fusto, collegamenti bullonati e saldati, e componenti accessorie;

-

Verifica della fondazione: rilievo e controllo del plinto di fondazione mediante scavi localizzati e indagini georadar, con ispezione della flangia di base e dei tirafondi.

WORKS ON ROPE

P&P performs work at height with access and positioning by means of ropes. Relief operations are also carried out, diagnostic cognitive investigations, installation of monitoring systems, safety of high-rise buildings and monuments.

The main environments in which we operate are:

- Metallic carpentry structures, cableway pylons, antennas, pylons

- Monuments

- Dams

- Bridges

- Quarries and mining activities

P&P has qualified personnel for the execution of temporary work at height with access and positioning by ropes for both the artificial and the natural environment as required by Annex XXI of the UNIQUE TEXT ON HEALTH AND SAFETY AT WORK No. 81 of 9 April 2008.